| Features |

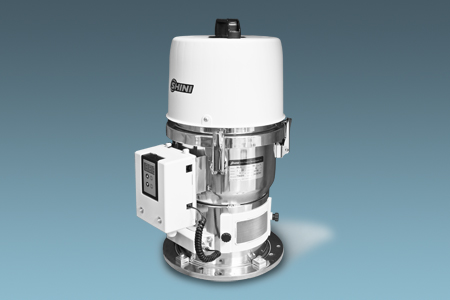

| SAL-1U~SAL-12U (-E) adopts carbon brush with fast rotating speed and large air quantity while maintain compact appearance, easy for transportation and installation. |

| Wire-control controller is convenient to use with automatic cleaning function. |

| Equipped with motor soft start function and carbon crush consumption prompt (except for three-phase motor). |

| Wire connection point for SPV-U. |

| Hopper and base mount positions are adjustable. |

| Differential pressure switch is employed and screener blockage alarm is available(Applicable to SAL-1U~12U(E)). |

| SAL-U has a reed switch, while SAL-U-E adopts photosensor switch with high sensitivity and stable quality. |

| All models equipped with hinged hopper lid that are connected by hinge for easy mesh cleaning. |

| SAL-3U and above model has a out dia.Ф 275 mm base, which can work with all "European type" hopper dryers except SHD-20U and all "Standard" hopper dryers above SHD-75. |

| SAL-1U has a out dia. Ф200 mm base, transitional flange must be mounted when this series work with SHD-20U/40U. |

| All SAL-U series machine has standard cloth mesh filter and auto-spraying dust cleaner. For SAL-6U and above models, it is available to select air accumulator to enhance the purging and reduce manually clean time. In order to maintain good function, SAL-U-3 series also has standard cloth mesh filter and motor reverse cleaning function without optionally select air accumulator and reverse cleaning kit. |

| Optionally provide multi-functional installation frame HMB-900 with 900 mm largest dia.adjusting range for selection. |

| Provide both standard and optional heat-insulative Euro collective hopper SCH-6U/12U/24U to mount directly on moulding machine feed port when magnetic proximity switch type hopper loader is used for material loading. |

| Reinforcing auto cleaning of air accumulator is optional (Applicable to SAL-6U/12U). |

| Buzzer is an optional selection (Applicable to SAL-U-3). |