| “Standard” Hopper Dryers - SHDSHD series Standard hopper dryers offer an effective and low-cost method for plastic material drying. Hot air is used to dry wet materials that due to moisture absorption during packaging, transportation, and recycling cycles. They can be directly mounted on the moulding machine for quick drying and space saving. For this series, hot air blows evenly from bottom to the top (both SHD-800 and SHD-1000 have down-blowing air pipe and accessible door for easy material clearance) of the hopper with capacity ranging from 12~1,000kg, Optional 24-hour timer is available for each model. |

| Standard Drying Loaders - SDLSDL series Standard Drying loaders integrate plastic drying and loading into one unit. Especially applicable to those large injection moulding machine which are placed in height limited workshop. This combination offers a group of standard photosensor hoppers, which can be used to load dried materials. Besides, SAL-900G is available for choose to realize the two-stage loading function. |

| Standard Hopper Dryers - SHD-USHD-U series hopper dryers adopt hot air down-blowing design and use stainless steel made material hoppers to avoid contamination. With this design, they are also ideally suitable for use with honeycomb dehumidifiers to dry engineering plastics. There are 25 models available, ranging from 20 to 8000 liters. |

| Drying Loaders - SDL-USDL-U series of drying loaders combine conventional hot air drying and two-stage conveying functions into a compact unit. It is particularly suitable for using with the big tonnage moulding machines when height restriction is concerned at the workshop. The SDL-U series has a unique function of two-stage conveyingf that can transport both raw material to its own drying hopper and dried material to the moulding machine. |

| Cabinet Dryers For cabinet dryers, materials to be dried are placed on the stainless steel made moveable material trays. During operation, process air will flow to heating wire and be heated up to required temperature, then flow through a manifold with evenly scattered holes. Moisture air is sent out through air exhaust port. It is designed to achieve an even drying effect. |

| Honeycomb_Dehumidifiers-SD-HSD-H series honeycomb dehumidifiers are mainly used to dry hygroscopic engineering plastics. A honeycomb-rotor is used to offer effective drying, which under ideal conditions, can supply dehumidified dry air with a dew-point lower than -40℃.This series comprises 15 models of honeycomb dehumidifiers, the largest of which can provide dry air up to a quantity of 4,000 m3/hr. |

| All-in-One Compact Dryers - SCDShini "optical" compact dryers combine the function of dehumidifying, drying and two-stage conveying into one single unit, specified for the production of "optical class" products, such as lenses, LCD backlight panel, compact discs etc. They feature honeycomb rotor for dehumidifying, ensuring continuous and constant low dew-point. Under ideal conditions, it can provide lower than -40℃ dew-point dehumidified air. |

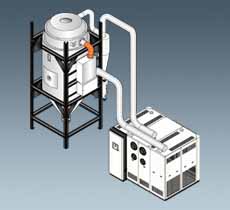

| Dehumidifying Dryers - SDDSDD series dehumidifying dryers combine dehumidifying and drying systems into a single unit. They have many applications in processing plastic materials, such as PA, PC, PBT, PET etc. All models feature SD-H honeycomb dehumidifiers with built-in process heater and insulated drying hopper. Under ideal conditions, it can provide dehumidified dry air with a dew-point lower than -40℃. |

| Compressed Air Dryers - SCADSCAD integrates plastic drying and conveying into one unit, which is especially applicable to vertical injection moulding machine and stand injection moulding machine when limited by height of the workshop. The SCAD adopts positive compressed air to load material so it has low noise level and low energy consumption. Euro design features classy appearance and easy for maintenance. The hot and dry air is formed by sending outfitted compressed air into pipe heaters. Unique up-blowing air pipe design makes hot air evenly spread out to achieve best drying effect. |

| Mould Sweat Dehumidifiers - SMD-HSMD series mould sweat dehumidifiers are designed to remove the moisture sweat from condensing on the mould surface. Forming of moisture sweat on the mould surface is due to the use of chilled water for reducing the moulding cycle time, particularly while moulding of the PET preforms. This series of machine uses honeycomb rotor to carry out dehumidifying function, which generates a dry airflow with dew point ranging from 0℃ to -10℃, and ensures the surrounding air of mould remaining in a low dew-point temperature. It provides constant low dew-point surrounding air to the mould surface all year round without being influenced by the change of seasons. |

| Modular Drying and DehumidifyingHA series consists of 22 kinds of hot air dryer whose drying air volume is 30~4000 m3/hr. By being flexibly combined with insulation hopper DH-U of different capacities, HA can become hopper dryers which have the same function with hopper dryer SHD-U.By Flexible combination in all size of insulateel hopper and dehumidifier, SD-PHC (with heater and controller) can become dehumidifying dryers which have the same function with SDD (with optional floor stand ). The dehumidifying dryers system consists of Honeycomb Dehumidifier SD-H-C and Hopper Dryer DH-U. It includes the floor stand version or customized plateform version. If there are too much dust contaminate the raw material, cyclone dust-collector ACF can be selected. |

| PET Crystallizers - SCRSCR closed-loop crystallizers are used for constant crystallization of un-crystallized PET regrinds or pellets. Processed materials can then be dried and dehumidified directly. Crystallized materials can be conveyed to material storage bin or into drying hopper. |