| Standard Self-contained Hopper Loaders - SALStannardd Self-contained SAL-330 / 360 series adopt single phase carbon brush motor with superior suction power and easy installation. It is particularly suitable for conveying new materials. SAL-430 / 460 series use a three phase inductive motor with low noise level and long service life. It also has an automatic motor reverse cleaning device. |

| Standard Separate-vacuum Hopper Loaders - SAL-GSAL-G series “Standard” separate-vacuum hopper loaders are suitable for conveying material over long distance. SAL-700G/800G/800G2 are for one to one combination, while SAL-900G/900G2 are for one to two combination. All models adopt stainless steel hopper to ensure no contamination to raw material. High efficiency high pressure blower features light weighted, durable, great suction power, easy installation and operation. |

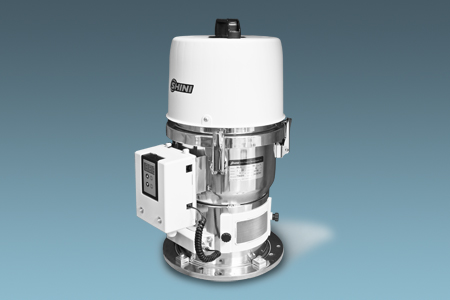

| Self-contained hopper loaders - SAL-USAL-U series self-contained hopper loaders are Euro design with stainless steel hopper to avoid material contamination. In addition, it has an attractive appearance, a sound-proof motor cover to reduce noise level and a top handle to enable convenient movement. Also the remote operation has been realized by using a detachable control panel. |

| Separate-vacuum Hopper Loaders - SAL-UGSAL-UG series separate-vacuum hopper loaders are based on the established design and now feature more attractive appearance, better performance, and improved ease of operation. The whole range comprises of seven models equipped with vacuum blower from 1 to 15 HP. Economy models can be offered on request. |

| Multi-station-Hopper-Loaders-SAL-UG122/124"One-to-Two or One-to-Four" Separate hopper loaders are designed and developed on the basis of original European separate-vacuum hopper Loaders. They feature more functions, easy to operate, and convenient to install. This model, equipped with a high pressure blower and four SHR-U-S type European central vacuum hoppers, is applicable to four dehumidifying and drying machines (dehumidifying dryer "SDD") or one gravimetric blender "SGB" to process plastic materials. Besides that , it can also realize the "One-to-Two or One-to-Four" way of conveying materials to different moulding machines or hoppers to greatly lower the cost. |

| Flexible Screw Feeders - SSCSSC series flexible screw feeders adopt motor-driven screws for raw material conveying, applicable to convey regrinds, virgin materials, powders and their mixtures with features of low noise level, easy installation and maintenance. Three models of SSC-40/50/65 available with max. horizontal conveying capacity of up to 1,200kg/hr. Besides using in plastic industry, they can also apply in food, chemistry, pharmacy and other various applications. |

| Venturi Loader - VL series venturi loader use fast flowing pressurized air to create a

vacuum that is used to convey various plastic granules. Air pressure is around

6~8kgf/cm |

| Bridge-breaking hopper-SBHBridge-breaking hopper is an auxiliary discharge device which mainly equipped on injection molding machine or extrusion molding machine. When material in large size and lightweight enter into the hopper of

injection molding machine will cause material bridging and difficult discharging.SBH -160U can make the material in compulsive loading and discharging. |

| Rotary Valve - SRVThe rotary valve is designed to feed powder materials and is the most precision feeding machine. Especially, it will get the optimum efficiency in the pneumatic conveying system or differental pressure condition. SHINI is devoting herself to creat higher pressure tightness seal, satisfying higher demands, providing better quality. |

| Single wire conveying system SWCSSingle wire conveying system is suitable for conveying new materials. It adopts European design and stainless steel hopper to prevent material from contamination. It’s powerful. With touch screen operation panel, it features simple and convenient operation. When equipped with 1-12 European vacuum hoppers SMHR-U, it’s suitable for “one-to-many” way of conveying materials to different molding machines or hoppers. |