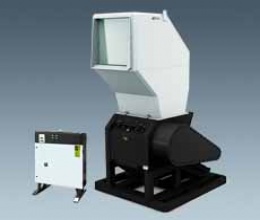

| Screenless Granulators - SG-14/24N/24TSG-14/24/24T series granulators operate in super low speed to cut materials into well-proportioned granules. There are least dusts produced in the cutting process. Multiple security devices ensure high safety grade; automatic reverse running function ensures continuous operation. This series of screenless granulators are suitable for granulating hard and thick materials. For SG-24T series, there are two gear motors and two cutting chambers to work simultaneously. It can not only granulate the sprues and waste material, but also has an effect on long and thin or tougher sprues materials. |

| Low-speed Granulators - SG-16N/16D/20NSG-16N/20N series low-speed granulators have paddle blades and staggered blades design for customer selection. They are mainly used for granulating sprues or rejects fed by pickers or belt conveyors beside the moulding machines. They feature low speed, high torque, low noise and dust level, excellent quality and performance. Machines are built to comply with CE safety standards. |

| Sound-proof Central Granulators - SG-23/30/36SG-23/30/36 series sound - proof central granulators are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding or extrusion lines. The machines feature optimized structure, easy operation, and quick blade replacement. Staggered rotating blades can easily grab and cut through materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum.This granulator has various models with wide application range to meet different customer’s demand. |

| Sound-proof Central Granulators - SG-43SG-43 series are suitable for centralized recycling of waste and rejected parts form injection, blowing molding and extrusion lines. This series feature compact design, easy operation and quick blade replacement. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level ensures low energy consumption. |

| Sound-proof Central Granulators - SG-50SG-50 series granulators are applicable to granulate various kinds of plastic materials from injection moulding, blow moulding or extrusion moulding. This series feature compact design, easy operation and quick blade replacment. It is great in motor power, cutting chamber size, and output capacity. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level. |

| Sound-proof Granulators - SG-70SG-70 series granulators are applicable to granulate various kinds of plastic materials from injection moulding, blow moulding or extrusion moulding. This series feature compact design, easy operation and quick blade replacement. It is great in motor power, cutting chamber size, and output capacity. Gradually inclined cutting and integrated power design offer a better cutting effect and a lower noise level. |

| Standard Series-SG-70E - SG-23E/30E/36ESG-23/30E series granulators have no significant differences with the standard model in construction and operability. The granulators feature quick blade change. They are suitable for centralized recycling of wastes or rejected parts from injection moulding, blow moulding and extrusion machines. Staggered blades can easily grab and granulate the materials. This design makes the machine work more efficiently and can reduce waste of energy to the minimum. |

| Standard-Series-SG-50BSG-50B series granulators are applicable to granulate various kinds of plastic materials from injection molding, blow molding or extrusion molding. This series features compact design, easy operation and quick blade replacement. Gradually inclined cutting and integrated power design offers a better cutting effect and a lower noise level. |

| Regular-Series-SG-70BSG-70B series granulators are applicable to granulate various kinds of plastic materials from injection molding, blow molding or extrusion molding. This series features compact design, easy operation and quick blade replacement. It is great in motor power, cutting chamber size, and output capacity. Gradually inclined cutting and integrated power design offers a better cutting effect and a lower noise level. |

| Budge-t_Series-SG-EB-SG-EBThis serie of SG-EB has no difference with the standard model in structure and operation for safety, but more of energy saving as well. The granulators are applicable to granulate various kinds of plastic materials from injection molding, blow molding or wasted materials. |

| SGS Series ShreddersSGS-S series of single-shaft shredders is an newly developed product line by SHINI. It can shred extra thick, tough and large solid materials. It can be applied in wide range, for example, recycling all kinds of materials, such as plastic, rubber and wood. The waste materials which are produced by the injection molding, blow moulding or extrusion moulding are also included. |

| Roll-feed Granulators - SGF-26SGF-29 series are applicable for granulating and recycling plastic films. After pressed toughly by the material feeding rollers, films are pushed and cut into granules for reusing. They feature easy operation, excellent quality, reasonable price and compact in size. Infinitely adjustable rotating speed reduces the dust, noise and abrasion of knives. Various kinds of safety devices meet the requirement of CE. |

| Belt ConveyorsShini manufactures five types of belt conveyor as follows under technical license from a leading european manufacturer.PNL series conveyors feature reliable performance and ease of operation and are suitable for use with CB or SV series conveying or as stand-alone unites. PNL-MS series belt conveyor with metal detector is a device which can detect the metal contained in the material during conveying and simultaneously activate the alarm. CB series conveyors feature reliable performance and ease of operation and are suitable for conveying sprues or finished products to a higher level beside the moulding machine. CBD series conveyors feature reliable performance and ease of operation and are suitable for conveying finished products to separator to separate product from its connecting sprues. The height is adjustable. SV series conveyors feature reliable performance and ease of operation and are suitable for conveying finished products fed from robots to a lower level. |