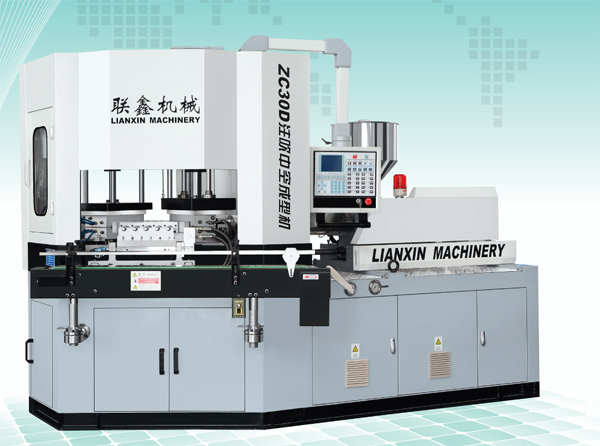

| ZC30D injection blow molding machine1.Adopt double pro portional variable displacement piston pump,can save 20% power than usual. 2.Adopt three-cylinder to lock the mold with the replenishing valve, can make the high and short cycle products. 3.Apply the double verticalpole and single and single horizontal beam to make enough rotation space,longer bottles,make the mold installstion easy and simple. |

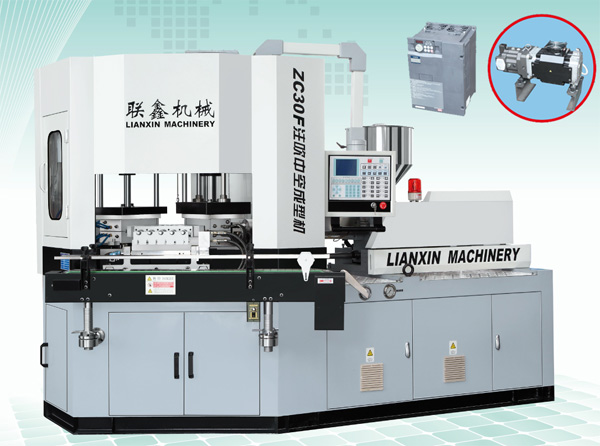

| ZC30F injection blow molding machine1.Adopt Electro-Hydraulic Hybrid Servo System Can save 40% power than usual.2.Adopt three-cylinder to lock the mold with the replenishing valve, can make the high and short cycle products. 3.Apply the double verticalpole and single and single horizontal beam to make enough rotation space,longer bottles,make the mold installstion easy and simple . |

| IBM30H injection blow molding machine1.Hydraulic system adopt electro-hydraulic hybrid servo system,can save 40% power than usual.2.Rotation device ,ejection device and flipping device adopt lasted servo motor,it can improve the performance stable,fast,no noise. 3.The screw is driven by servo motor, ensure machine action efficient, speed highly and energy saving. 4.Apply the double vertical pole and single horizontal beam to make enough rotation space,make the mold installation easy and simple. |

| ZC50C injection blow molding machine1.Adopt Electro-Hydraulic Hybrid Servo System Can save40%power that usual.2.Apply the double vertical pole and single horizontal beam to make enough rotation space, longer bottles, make the mold installation easy and simple. 3.The injection mold adopt the double assistant cylinder open-close mold, ensure the stable and quick moving. The clamping force is three points equal distribution. high-speed hydraulic-added valve can increase the clamping speed. |

| ZC50H injection blow molding machine1.Hydraulic system adopt electro-hydraulic hybrid servo system, can save 40% power than usual.2.Rotation device, ejection device and flipping device adopt lasted servo motor,it can improve the performance stable, sovle the problem of oil leak which is caused by the seal aging deterioration. 3.IBM5OH clamping cylinder is under rotation table, which advance for mould change &product clean,Open-close mold adopt double horizontal beam and for vertical pull rod. 4.Open-close mold adopt assisstant cylinder do the actions, main cylinder purge and lock mould. It can do the action in high stability and speed. Cylinder clamping force been more balance to improve machine better inflexibility. 5.Melt back pressure is controlled by cnc, can work more convenient and reliable. |

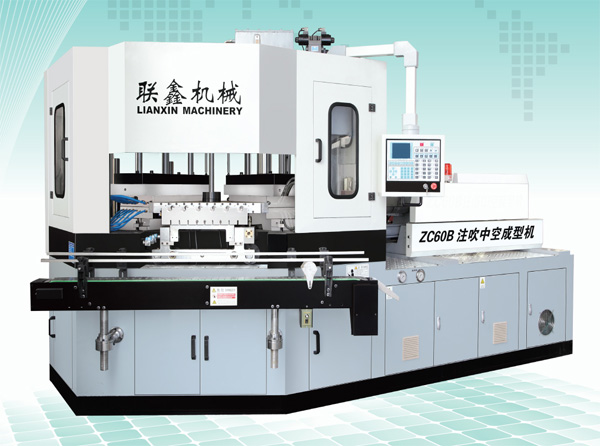

| ZC60B injection blow molding machine1.Hydraulic system adopt electro-hydraulic hybrid servo system,can save 40% power than usual.2.Rotation device ,ejection device and flipping device adopt lasted servo motor,it can improve the performance stable,fast,no noise. 3.The screw is driven by servo motor, ensure machine action efficient, speed highly and energy saving. 4.Apply the double vertical pole and single horizontal beam to make enough rotation space,make the mold installation easy and simple. |